We are now accustomed to having intelligent connected devices from smartphones to smart watches to smart cars. When it comes to essential services like water and electricity, we are still relying on age old infrastructure designed at a time when electromechanical systems were the state of the art. Its time we upgrade our age-old electrical systems to become smart and intelligent.

The challenges accentuated by COVID

During this COVID crisis we are all practising social distancing. Essential services that are functioning are doing so with limited manpower. Keeping essential services up and running during this time is a difficult task.

Automation is now critical to add resilience and reliability to our essential services. This is not your typical automation that improves quality and operational efficiency. This is automation for survival and sustainability.

Electricity is one of these essential services. It is essential to every single function in every single organization. If used without proper checks it leads to increased downtime and asset loss. There is a direct risk of fires and casualties. In COVID with our electrical maintenance team not available we are at higher risk.

Digital transformation for electrical safety in the 21st century

Electrical safety is an area that is ripe for transformation. We use electromechanical protection devices that are a century old. They only act to disconnect electrical supply in case of 3 of the known 12 critical electrical risks. Worse, when they trip there is no warning, no guidance or recommendation on what to do next. We rely on manual intervention by trained experts (our electricians, who are not able to visit as we practice social distancing.

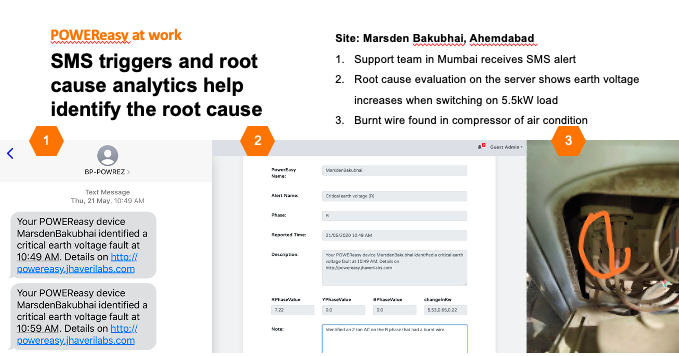

Intelligent IOT based solutions are now available that use edge automation and cloud analytics with trained AI/ML models to perform the job of an electrician. To help identify what went wrong and protect you from all 12 critical electricaal risks

Smart electrical audits are necessary for:

- Early diagnosis and predictive maintenance: It will allow for minor interventions that could avoid catastrophic failures and shutdowns in the future.

- Remote monitoring: This is social distancing. Even if a site visit is required data will allow for a fixing problem precisely and avoiding future site visits

- Automated auditing: To enable safety checks without need for a person visiting a site.

- Corrective action: To enable critical protection even when an electrician is unavailable.